No.2 Building, Jinsong One Road, Qingdao, China +86-532 55718566 [email protected]

Kingway Engine Conversion Department Kingway Engine Conversion Department has been committed to the research and development of gas engines, has developed the controller ECU suitable for different gas fuels, has completely independent intellectual pr...

Contact Us

Kingway Engine Conversion Department

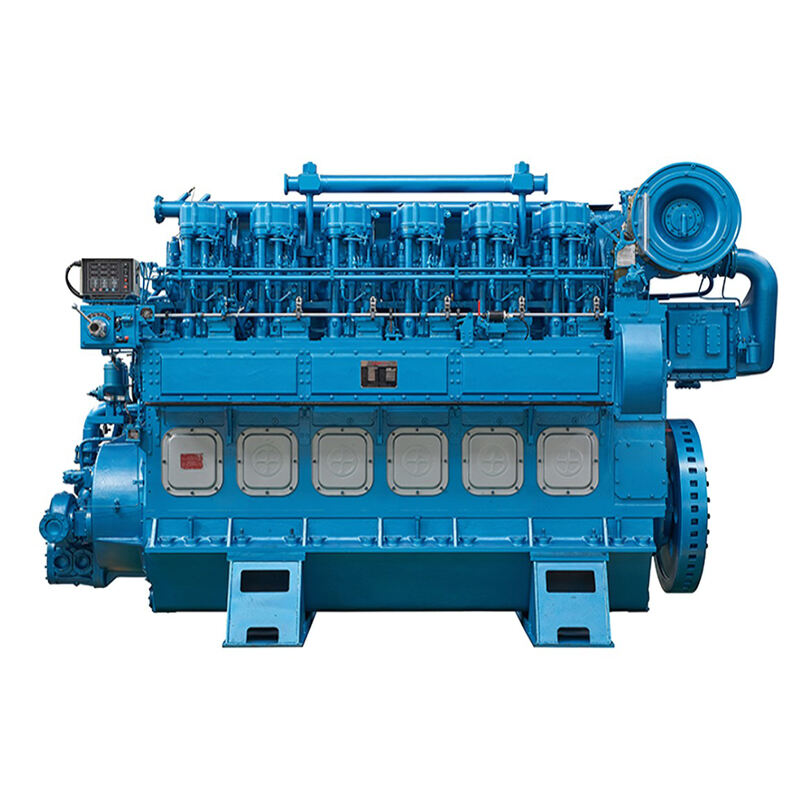

Kingway Engine Conversion Department has been committed to the research and development of gas engines, has developed the controller ECU suitable for different gas fuels, has completely independent intellectual property rights.

We can not only provide the whole gas engine, but also providediesel engine modification service and design, manufacture and installation of the gas supply system (gas skid station).

With the strong technology, any type of diesel engine can be successfully convert into single fuel or dual fuelgas engine, there is no fundamental performance difference compared to the original machine, and can be customized according to the working and environmental conditions, so the actual use effect exceeds the original machine.

High Qualityand Safety

Always been our persistent pursuit goals

Single fuel generator set:

Single fuels include LPG, CNG, LNG, Biogas and other flammable gases.

We can customize the gas supply method of fuel (Single-point mixing or multi-point mixing injection) according to the actual needs of customers.

Dual fuel generator set:

Dual-fuel generators can be used in combination with diesel and gas under normal conditions.

The blending substitution rate can reach 80%, and the average rate is 55%.

Can switch to single diesel fuel mode without gas fuel.

Note: Blending substitution rate%:

In the blended state, the proportion of gaseous fuel in the total fuel (gas + diesel).

Safety protection system of gas genset:

* Gas engine protection (water temperature, oil pressure, oil temperature, overspeed, etc.);

* Gas engine inlet protection against fire returning, overpressure, and explosion&vibration protection;

* Emergency cut-off and fire arresting device for gas pipeline;

* Gas engine exhaust temperature control;

* Emergency shutdown of the genset;

Core technical advantages of gas genset:

1. Independently develop core control unit ECU of the gas engine.

* Single fuel ECU using thin combustion technology (single-point hybrid & multi-point hybrid)

The system integrates high-energy ignition and ignition angle control, and can be pre-installed with aexplosion & vibration protection management system;

The system uses a wide-area line oxygen closed-loop system to dynamically monitor A / F in real time to reduce emissions;

The system integrates digital speed regulation, and the transient response time to control the gas injection valve is only 2ms;

* Dual fuel ECU,

Blending of various fuels such as diesel & LPG, diesel & NG, diesel & Biogas;

Digital speed control and ignition independent control system are adopted to fully ensure the reliability of dual fuel applications;

PLC programmable control makes the fuel conversion stable and fast;

The above system is equipped with an exhaust temperature adaptive system to avoid excessive gas combustion and achieve genset protection;

2. Diesel engine convert to gasengine

Use Converge to analyze the simulation model of the combustion chamber of the engine, and analyze the intake and exhaust models;

Recalibrating the supercharged engine to obtain different gas power..

Self-design gas engine supporting parts, gas high temperature resistant materials;

Self-design marine diesel engine convert to fan belt drive system for land-based genset;

Configure air intake system, overpressure and explosion-proof system for gas engine.

3. LPG genset& dual fuel gas genset

LPG generator set;

Establish a combustion model suitable for LPG through Converge analysis software;

In order to adapt the A / F control strategy of the LPG engine, optimize the design of the combustion chamber;

Multi-point mixed injection mode is adopted to achieve more accurate injection volume and effectively avoid the bursting and returning of fire.

Dedicated gas skid station for LPG system;

Dual fuel gas genset;

The dual-fuel ECU independently developed by the company has successfully realized precise and automatic fuel switching;

Multi-point mixed injection mode is adopted, with a substitution rate of 30% -80% and an average substitution rate of 55%;

The power of dual fuel is equivalent to that of the original machine, and higher cost performance is very obvious;

4.Extra large / super large gas genset

Adopt the company's self-developed pre-combustion combustion system to realize the secondary ignition of large-bore engines;

Adopt several group explosion& vibration control system with American technology + gas CAN bus ECU control;

Multiple gas safety protection systems (overpressure, explosion protection, gas leakage, etc.);

Remote network positioning monitoring system for engine dynamic parameters (providing 24h guarantee service);

5. Gas supply skid-mounted system for gas genset:

Establish a gas supply system with stable pressure, reliable performance and safety

Prerequisites for engine operation.

According to the needs of customers, we can design various skid-mounted stations for customers such as vaporization, decompression, desulfurization, dehydration, metering, odorization, and fast charging.

Copyright © Qingdao Kingway Industry Co.,Ltd. All Rights Reserved — Privacy Policy